One Technology.

Endless Applications.

Automated UV-C + Ozone systems that reduce up to 99.9993% of shoe-borne microbes—protecting your people, facilities, and products across every industry.

From hospitals to food plants, pharmaceutical labs to transportation hubs—our proven dual-technology approach creates cleaner, safer environments without chemicals, training, or ongoing maintenance.

Industries We Serve

Proven microbial reduction technology across multiple sectors

Healthcare / Long-term Care

Pathogen mitigation and indoor environmental quality

Pharma / Biotech

Biosafety and microbial control for cleanrooms

Food Processing

Hygiene, sanitation, and audit readiness

Controlled Environment Agriculture

Biosecurity for indoor grow operations

Transportation

Microbial reduction in high-traffic transit areas

Government Services

Mission-critical sanitation for emergency response

Automated UV-C + Ozone Technology That Works While You Do

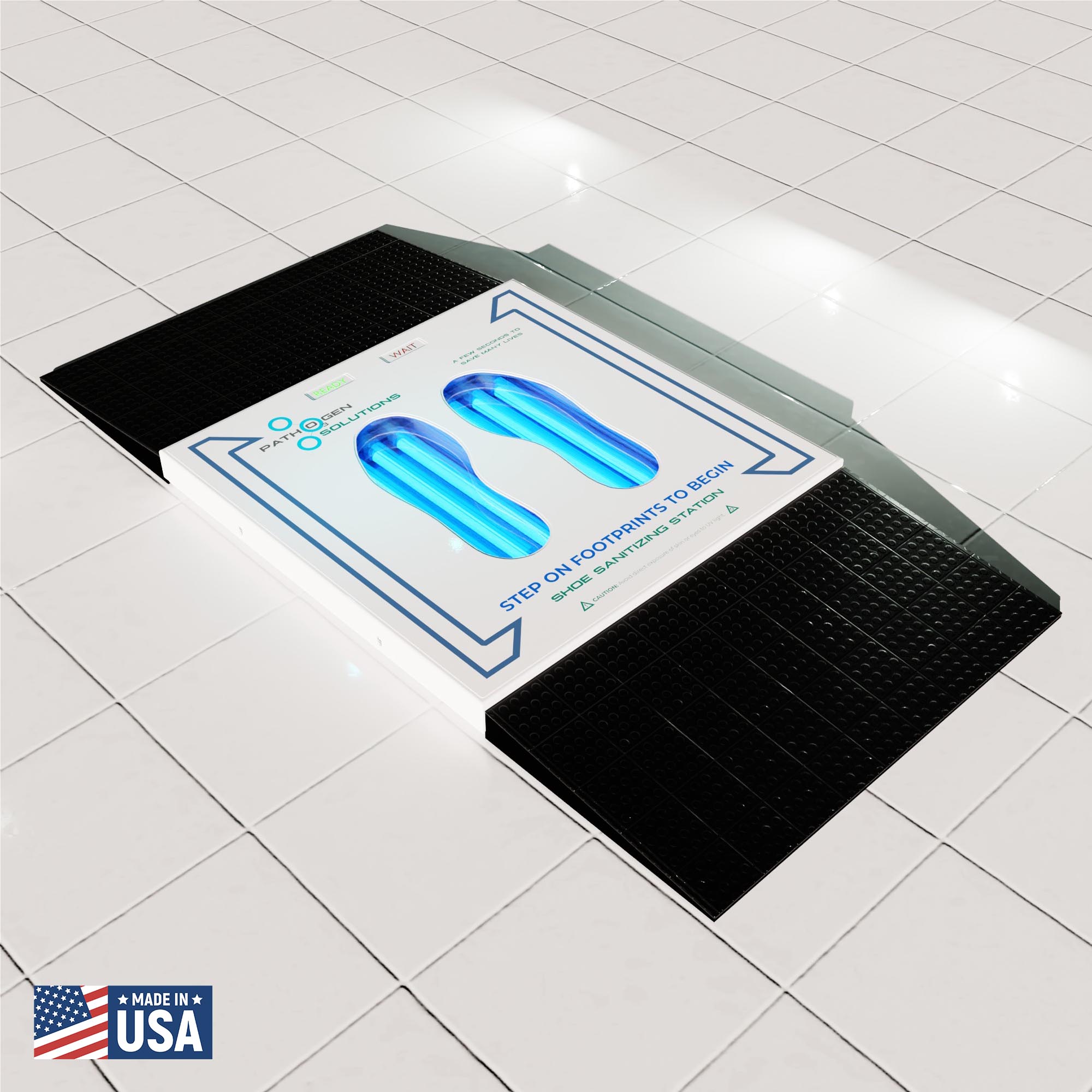

The UVZone system delivers continuous pathogen reduction through automated UV-C + Ozone dual technology. Installed at entry points, it reduces shoe-borne microorganisms as people walk through—combining 254nm UV-C light with controlled ozone for maximum efficacy. No chemicals, no training, no disruption to your operations.

Subscription-Based Model

Get enterprise-grade pathogen reduction without the capital expense. Our subscription includes everything you need:

- Zero upfront equipment costs

- Installation and setup included

- Ongoing maintenance and support

- Lamp replacements and service

- Predictable monthly pricing

- Scalable across multiple facilities

How It Works

Three simple steps. Zero training required. Instant pathogen reduction with UV-C + Ozone.

See UVZone in Action

Watch how easy it is to reduce pathogens at every entry point

Step On

Walk onto the UVZone mat at any entry point

Pressure sensors detect footwear and activate the system automatically

UV-C + Ozone Treatment

Dual-action UV-C + Ozone technology treats shoe soles in 6-10 seconds

254nm UV-C light and controlled ozone work synergistically to reduce pathogens

Walk Through

Continue into your facility with reduced microbial load

Up to 99.9993% reduction verified by independent labs

Free consultation • No obligation • Custom quote

Calculate Your ROI

See how much you could save by preventing contamination events with UVZone shoe sanitization

Hospital-acquired infections, patient safety incidents

Total workforce entering your facility daily

Include confirmed incidents, near-misses, and suspected contamination events

Total locations requiring UVZone systems (enterprise pricing available)

Recommended System Configuration:

• 2 UVZone units per facility

• 2 total units across all locations

Based on 1 unit per 75 employees for optimal coverage

Your Estimated Results

• System investment: $12,000

• Annual subscription: $2,400

• Net annual benefit: $249,600

Ready to see these savings in your facility? Get a custom quote based on your specific needs, facility layout, and deployment requirements.

* Estimates based on industry-specific contamination costs and independent lab efficacy data. Actual results vary by facility. Conservative estimate assumes 70% reduction in contamination events based on 99.9% pathogen elimination efficacy from NSF International testing. Individual results depend on facility conditions, compliance, and implementation.

The Data Speaks for Itself

Independent lab testing and real-world results prove UV-C + Ozone effectiveness

Third-Party Lab Verified Efficacy

NSF International, CREM CO. Labs, Microchem Labs

| Pathogen | % Reduction | Log Reduction | Time | Lab |

|---|---|---|---|---|

| Candida auris | 99.9993% | 5.16 log₁₀ | 10 seconds | NSF International |

| E. coli (ATCC 11229) | 99.9989% | 4.96 log₁₀ | 10 seconds | NSF International |

| CRE (K. pneumoniae) | 99.9986% | 4.86 log₁₀ | 10 seconds | NSF International |

| Salmonella enterica | 99.9980% | 4.81 log₁₀ | 8 seconds | Microchem Labs |

| MRSA (ATCC 33592) | 99.9969% | 4.51 log₁₀ | 10 seconds | NSF International |

| Murine Norovirus | 99.9951% | 4.31 log₁₀ | 6 seconds | CREM CO. Labs |

| Listeria monocytogenes | 99.9940% | 4.21 log₁₀ | 8 seconds | Microchem Labs |

| Cronobacter sakazakii | 99.9910% | 4.04 log₁₀ | 8 seconds | Microchem Labs |

| Human Coronavirus 229E | 99.9796% | 3.69 log₁₀ | 8 seconds | CREM CO. Labs |

| C. difficile (spores) | 99.9960% | 4.40 log₁₀ | 10 seconds | NSF International |

* Full test reports available upon request. Testing conducted 2019-2021.

Certifications & Compliance

Get detailed efficacy data for your specific pathogens of concern

Backed by Independent Research

Multiple third-party studies from credentialed laboratories validate UV-C + Ozone efficacy across diverse pathogen types and real-world conditions

Efficacy of UV-C + Ozone Against Healthcare Pathogens

Christine Greene, MPH PhD, Bryan D. Schindler, PhD

NSF International - Applied Research Center

Inactivation of Influenza A Virus Subtypes

Nader M. Sobhy, Angie Quiñonez Muñoz, et al.

University of Minnesota - Veterinary Diagnostic Laboratory

Swine Virus Inactivation on Footwear Materials

Angie Quiñonez Muñoz, Trisha Sharma, et al.

University of Minnesota - College of Veterinary Medicine

Murine Norovirus Elimination Study

CREM Co. Laboratories

CREM Co. Labs, Ontario, Canada

Technical Specifications

Specifications verified by . UV-C output measured at glass surface. Ozone concentration measured under and around shoe base.

Broad-Spectrum Antimicrobial Efficacy

Gram-Positive Bacteria

- MRSA (99.9969%)

- VRE (99.9863%)

- C. difficile spores (99.9960%)

Gram-Negative Bacteria

- E. coli (99.9989%)

- P. aeruginosa (99.9976%)

- CRE (99.9986%)

- Salmonella (99.9980%)

Fungi & Yeasts

- Candida auris (99.9993%)

- Aspergillus brasiliensis (96.1744%)

Viruses

- Murine Norovirus (99.9951%)

- Human Coronavirus 229E (99.9796%)

- Influenza A (93-99%)

- PRRSv (≥99%)

- PEDv (98.55-99%)

What Our Clients Say

Real results from facilities across multiple industries

“Patho3Gen's UVZone system has transformed our infection control protocols. We've seen a dramatic reduction in HAIs since implementation.”

“The ROI was clear within 6 months. Lower contamination rates, reduced downtime, and peace of mind for our entire operation.”

“Our clean room validation results have never been better. Patho3Gen delivers consistent, verifiable sanitation every single time.”

What You'll Get

- Free facility assessment

- Custom system design

- ROI analysis for your facility

- No-obligation quote

- Implementation timeline

- Financing options available

Prefer to talk now?

Get Started Today

Fill out the form below and we'll contact you within 24 hours