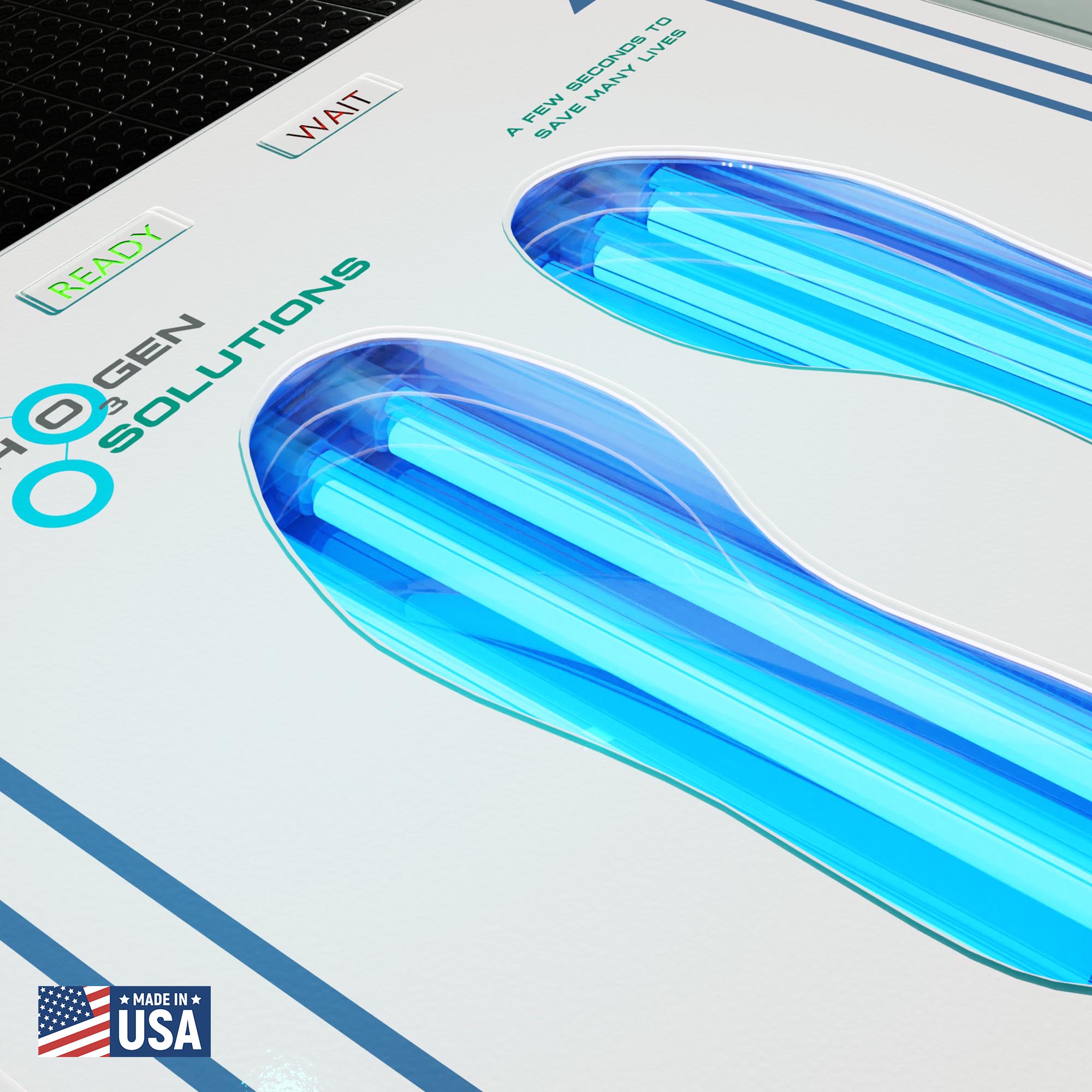

Shoe Sanitizer Technology

Industry-leading automated shoe disinfection using dual-action UV-C and ozone technology for superior pathogen mitigation

Dual-Action Disinfection System

UV-C light and ozone work together to provide comprehensive pathogen reduction on all shoe types

UV-C Light at 254nm

Germicidal UV-C light penetrates microbial cell walls and damages DNA/RNA, preventing pathogen replication and rendering them unable to cause infection.

Ozone Generation

UV-C light at 185nm converts oxygen into ozone (O₃), a powerful oxidizing agent that penetrates crevices and porous materials, oxidizing proteins and lipids in microbial cells.

Why Choose Automated Shoe Sanitizing?

The most effective solution for preventing pathogen transfer via footwear

Proven Efficacy

Up to 99.9993% pathogen reduction against MRSA, C. diff, Salmonella, Listeria, and more

Rapid Treatment

Complete disinfection in 6-10 seconds with no impact on workflow

Zero Maintenance

No chemicals to refill, no mats to clean. UV-C lamps last 9,000+ hours

Automated Operation

Pressure sensors activate automatically. No buttons, no training required

All Footwear Types

Works with boots, shoes, sneakers—all materials and tread patterns

FDA Registered

Class II medical device registration for healthcare and food processing

Product Specifications

Engineered for maximum efficacy and ease of use

Ready to Protect Your Facility?

Contact us for pricing, technical specifications, and implementation support